Kleentek Electrostatic oil cleaners เครื่องทำความสะอาดน้ำมัน

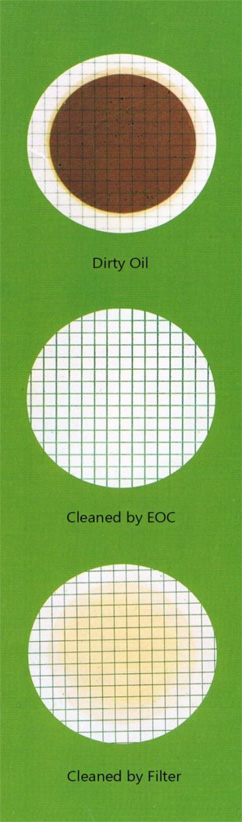

Conventional filters cannot remove sufficient oil contaminants in order to achieve the required oil cleanliness. Kleentek Electorstatic Oil Cleaner (EOC) and Dehydration units (DH) condition hydraulic oil and lubricating oil and prevent the hydraulic system failures such as valve malfunction, pump failure and oil leakage, as well as bearing wear.

The benefits of EOC

-

- Reduced machine downtime

- Reduced maintenance cost

- Improved product quality

- Extended oil life

- Extended seal and o-ring life

- Energy cost saving

- Eliminates servo valve failures.

Electrostatic Oil Cleaners (EOC)

Electrostatic Oil Cleaners (EOC) remove contaminants like oil oxidation products to sub-micron levels and also remove deposits from system internals such as the oil reservoir and pipework.

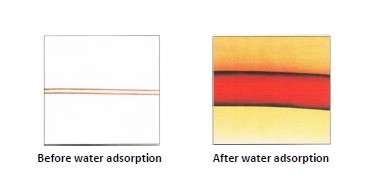

Oil Dehydration

Oil Dehydration units remove water from oil. We manufacture two different types of oil dehydration units.

IDH

DH series are water absoption type dehydration unit. High absorbent fiber element absorbs water from oil effectively.

IDH-KS

DH-KS series are water separation type dehydration unit. The aggregating element agglomerate emulsified water to larger droplets and water separating element separater water from oil.

KF Unit

Utilizing multiple layered charged nonwoven fabric of different absorbance, the KF removes contaminants in fluids regardless of sizes. The KF can be used for cleaning fluids such as mineral oil, water glycol, water soluble fluid and wash oil.

EOC working principles

The EOC makes use of principles that the contaminants floating in oil are electrically charged and trapped by electrodes. The particulates floating in oil may be electrically classified into three types, i.e., those charged positively or negatively, or neutral one. The positively or negatively charged ones are attracted to the electrodes of opposite charges (electrophoretic migration) and neutral ones are attracted to the strong electric field generated by pleated type collector (dielectrophoretic migration)

Water Separation Type

The aggregating elements made of a specialty material convert emulsified water to larger droplets followed by formation of a water curtain by the separating elements, and the water thus isolated precipitate out to separate. This type of unit is used when water is contained over 2000ppm or constantly entering, and removes water down to 1000ppm.

Water Absorption Type

Fiber element of high water absorbance in use absorbs water by several times as much as its own weight. This unit is utilized when the water content is less than 2000ppm and down to 500ppm